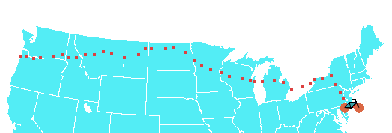

| CTN TransAm 09 40 days on the road 3750 miles by bicycle |

|

Chris Nadovich's 2009 Transamerica Bike Tour.

Contact Me

Mon, 16 Feb 2009

Installing Fenders and Racks on my Atlantis

![[p2060581]](/galleries/morebike/output/thumb-p2060581.jpg) Don't get me wrong, the Atlantis is great. I don't regret getting it. There

are just some minor issues that kept the experience from being perfect. One

of them was installing fenders and racks.

Don't get me wrong, the Atlantis is great. I don't regret getting it. There

are just some minor issues that kept the experience from being perfect. One

of them was installing fenders and racks.

When I ordered my Atlantis, I ordered it with brakes, handlebar, wheels, gears, and fenders. I paid a stiff "assembly fee" and, indeed, almost everything was assembled when I received the bike. Of course, for shipping, some parts needed to be partially removed from the bike in order to best fit in the box -- the handlebars were popped off and the front wheel was to the side. But other than the the shipping rearrangement, everything was assembled. Everything with one exception: the fenders.

Now, I can almost see justification for this. The front fender, would definitely need to be removed for shipping. And maybe the rear fender too. So why bother assembling the fenders just to remove them?

The problem with that reasoning is that it assumes the fenders can be assembled. When I paid that assembly fee, at least in my mind, it was most importantly a fee to assure that the parts all fit. Actually putting them together was secondary. If I just wanted a bag of parts, I would have done better to buy them all from Nashbar. Having RivBike assemble them meant that RivBike was on the hook to be sure they all played together.

For a few reasons fenders didn't quite play right out of the box. I had to wrangle with them quite a bit.

The first reason they didn't play initially was because not all the fender parts were shipped to me -- one rather critical one was missing. Rather than shipping the fenders in their original package, unopened, RivBike cut up the fender carton and taped it in various locations inside the shipping box. Apparently, in the process of doing that, a piece fell out onto their shop floor: the rear fender top mounting bracket.

RivBike also forgot to ship the bike's seatpost as I noted elsewhere, so my brow got real wrinkled when another part turned up missing. I considered writing Grant to alert him to this second omission, but in the end I decided to come up with my own superior system for the fender top bracket.

Another reason the fenders didn't play is because all the threaded braze-on eyelets on the Atlantis were painted on the inside. I had to scrounge up a M5 tap (not exactly something you can get at Home Depot) and clean out all the threads before any screws would go in. If RivBike had trial-assembled the fenders, they would have encountered this problem.

In the end, I got it all to work adequately well on my 58 cm Atlantis with SKS fenders and Tubus racks. YMMV on different frame sizes or with different gear.

Here's what I did.

To begin with, I needed a bunch of extra parts, mostly 5mm hardware. Local home centers and Tru-Value are near useless when it comes to metric tooling; you need to buy metric stuff off the Net. My favorite catalog vendor for this is McMaster Carr. They sell practically anything when it comes to hardware. I bought the following items from them:

8302A16 Uncoated Metric HSS Spiral Point Tap 5 X .8 mm 91111A124 Lock Washer for Socket Head Cap Screw M5 Screw Size 91116A140 Large-OD Flat Washer M5 Screw Size, 5.3mm ID, 15mm OD 93475A240 Flat Washer M5 Screw, 5.3mm ID, 10mm OD 93625A200 Nylon-Insert Hex Locknut M5 Size 92095A216 Button Head Socket Cap Screw M5 Size, 25 mm Length 94669A077 Aluminum Unthreaded Round Spacer 10mm OD, 8mm Length, M5 Screw Size

All the hardware was 18-8 stainless steel, except for the spacer and tap.

Using the tap in a tap handle, and a little oil, I cleaned out the threads on all the eyelets I was planning to use. Not sure what they use for a primer, but the gloss eggshell paint on the Atlantis is very brittle and loosely attached. It chips off quite easily. Ahhh, those Ten Speed Drive Imports Imron paint jobs, with chrome dropouts, forks, and chainstays. The first time I tightened a skewer on the eggshell painted dropout of an Atlantis: Craaaack! You ran see the result in this photo.

That photo also shows how the front rack and fenders mounts to the fork. All the hardware shown is standard hardware that comes with the Tubus rack and SKS fenders. Nothing from McMaster yet.

The mounting of the front fender at the fork bridge is shown here. This is not completely stock hardware. I added the McMaster 91111A124 lock washer and 93475A240 flat washer. Not seen is a shoulder bushing from an old Campy Record brake set that I inserted into the large fork crown hole to force the screw to be centered. Without the bushing, the fender position would be more likely to slide around. I suspect McMaster might have a useful bushing or T-nut for this application, but I didn't need it because I have this huge box of old parts and the Campy bushing was perfect for the job.

![[p2060583]](/galleries/morebike/output/thumb-p2060583.jpg) To the right is a view of the front wheel with fender and Tubus Tara rack. A sharp eye

will notice the

brackets

that hold the horizontal rack members. These brackets are in lieu of braze-on

holes at 165mm above the dropout braze-on. Grant from RivBike gave me his

standard rhetoric about how there is "no standard" for these mid-fork

eyelets. Sometimes you have to go hmmmm. My Bianchi has 165mm spacing

for the mid-fork eyelets. Gary's Long Haul Trucker has 165mm spacing. Rivendel

sells Tubus (but not their front racks). Hmmmm.

To the right is a view of the front wheel with fender and Tubus Tara rack. A sharp eye

will notice the

brackets

that hold the horizontal rack members. These brackets are in lieu of braze-on

holes at 165mm above the dropout braze-on. Grant from RivBike gave me his

standard rhetoric about how there is "no standard" for these mid-fork

eyelets. Sometimes you have to go hmmmm. My Bianchi has 165mm spacing

for the mid-fork eyelets. Gary's Long Haul Trucker has 165mm spacing. Rivendel

sells Tubus (but not their front racks). Hmmmm.

Anyway, I talked to Wayne over at The Touring Store. He sold me my Tubus racks. Wayne said that he has a dozen or so people a year complain to him that their Atlantis won't take a Tubus front rack. Not to worry, he has these nifty brackets that make it all work. And they do. I added a few of the McMaster 93475A240 flat washers under the screw head and nut. Without them, I had difficulty holding the nut with a box wrench as I turned the hex screw as the nut sinks into the recess in the bracket body. Perhaps that recess should be hex shaped -- or better yet, pressed with a helicoil.

Listen to me. I shouldn't complain. Without these nice brackets I'd've been forced to sink so low as to use P-brackets or (shudder) hose clamps. Grant, either reconsider your position on 165mm mid-fork eyelets or sell a low rider rack that fits your bike.

It took a while to align everything on the front wheel. RivBike advertises the 622-47 Schwalbe Marathon as being 37.79mm wide, based on a measurement made by their $250 Mitutoyo Absolute Digimatic. Well, the tape measure with centimeter scale that I bought for $0.99 off Home Depot's closeout table says the Schwalbe they sold me is more like 45mm wide. This is a pretty wide tire and it just barely works with the SKS fenders. Min clearance is about 8mm. I'm a little uncomfortable with that and I ordered the next smaller size Marathons from Peter White, along with a new wheelset. I'll use the ones RivBike sold me as a backup -- or sell them on eBay.

With my front rack mounted, I now turned to the rear rack. This was a bit more problematic as I was missing the seat-stay bridge mount bracket. Not to worry. Those 8mm long 94669A077 spacers from McMaster were exactly what was needed here. After painting them RustOleum gray, I ended up using them both at the seatstay mount point, and at the chain stay mount point. I added the Large-OD 91116A140 washers to both sides of the fender, and used the 92095A216 button head screw to get better tire clearance than the standard hex head. A 91111A124 lock washer and a dab of blue LockTite was added for security on the seatstay mount. On the chainstay mount I used a 93625A200 Nylon Insert "aircraft" nut and a locknut.

Down by the dropout, things were pretty much stock. The only thing I added was a large OD washer to the fender mounting screw as you can see here. I may someday replace these large washers with a proper bushing machined to fit the fender stays, but for now this works.

That's about it. All in all I spent about 8 hours and twenty bucks getting fenders and racks mounted on my Atlantis. You might say that's not too much of a big deal, and it really isn't. I doubt RivBike would have added the IMHO necessary extra hardware if they had done the mounting. I'd've been forced to re-do it and that would have been even worse. All I really can gripe about are the issues with the paint inside the eyelets and the missing parts. That's hardly a biggie, but when you pay this much for a pre-assembled bike, it's the little things you are paying for.

RivBike reports they are being squeezed by exchange rates and other business issues. I for one feel that their bikes are not overpriced given that they are unique. I could not find another lugged steel bike of this quality that met my equipment requirements. I suspect that many of RivBike's customers feel the same way. Grant should charge what he needs to charge to maintain quality and still sell these bikes profitably. If the market won't support that -- if the market doesn't want this kind of quality -- then maybe Grant could lobby Congress for part of the bailout package.